American Journal of Roentgenology – September 2017, Volume 209, Number 3

This letter to the editor from Moritz Wildgruber, one of the most senior researchers on the subject of the origins of thermoplastic catheter complications, describes how other recent studies have defined the hypothesis of how the disbursement of barium sulfate within the construction of the catheter tube is the mechanism for vulnerability of the catheter.

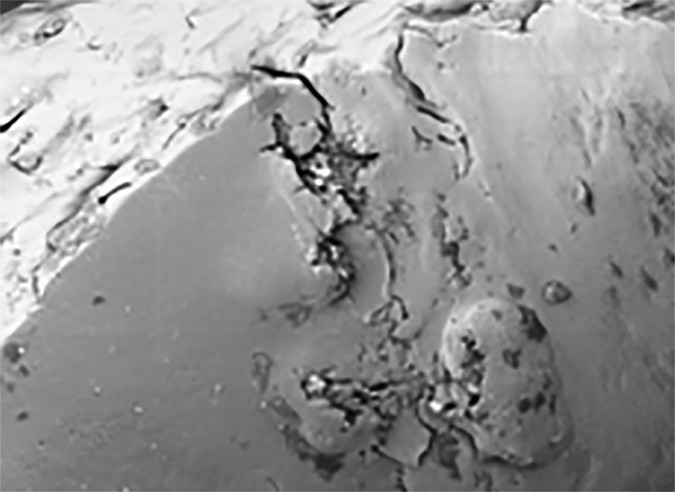

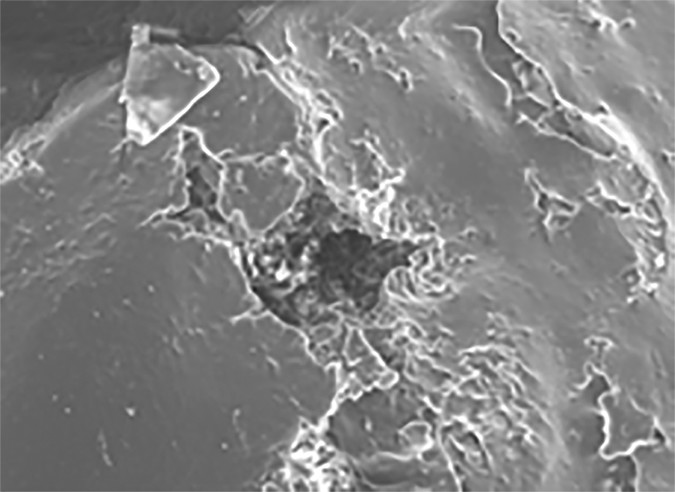

The loss of BaSO4 particles between the silicon bonds essentially leaves microscopic holes in the catheter, leaving areas of increased vulnerability that render the catheter prone to rupture.

American Journal of Roentgenology

September 2017, Volume 209, Number 3

Letter

The article by Busch et al. [1] describes material failure of implanted silicone port catheters with subsequent rupture in 3.4% of a total of 553 patients. The results are in agreement with a 3.2% rate of mechanical failure of silicone port catheters [2]. My colleagues and I [3] have similarly found that catheter rupture occurs more frequently in silicone than in polyurethane catheters. The study by Busch et al. adds greatly to existing reports on port catheter–associated complications that have predominantly focused on thrombotic and infectious complications. Busch et al. have elaborated well the fact that the probability of rupture increases with longer dwell time, and they conclude that the cause of material failure is unknown. I would like to draw attention to recently published results from the field of materials sciences that answers in part the authors’ question.

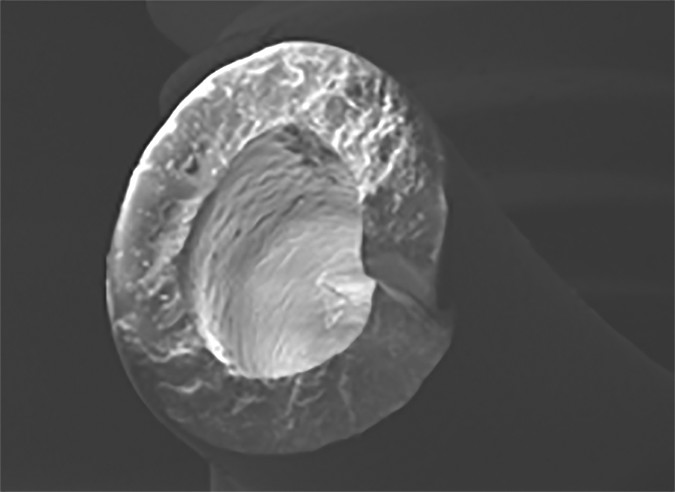

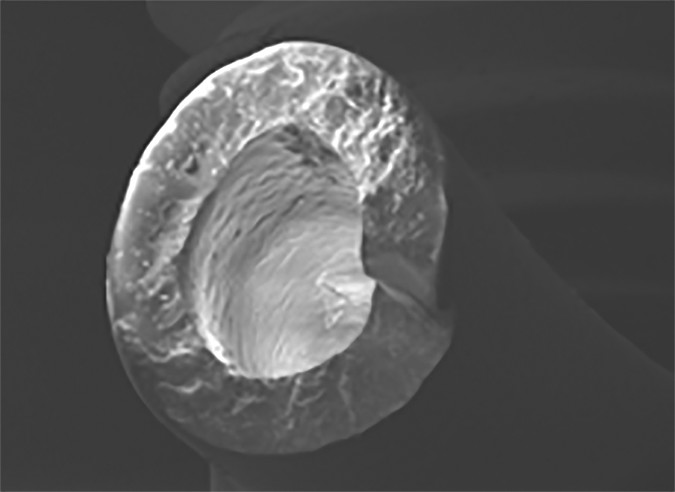

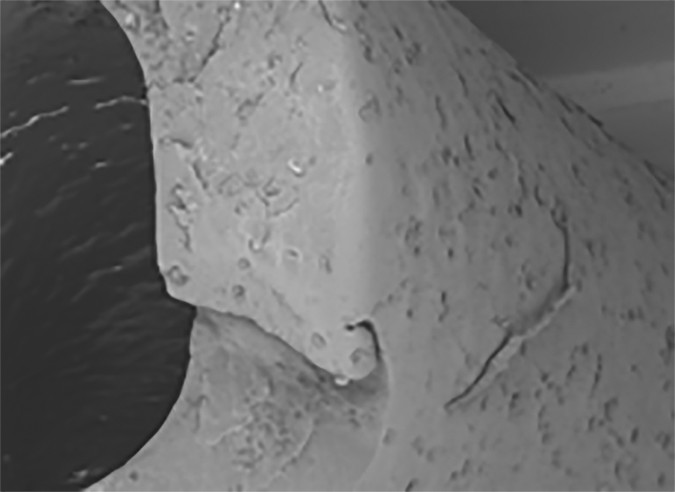

Braun et al. [4] performed a set of experiments investigating the mechanical properties of both de novo and explanted port catheters. They found clear correlation between material properties and clinical performance. Specifically, both native catheters exposed to moderate mechanical stress tests and explanted catheters from cancer patients had a progressive loss of barium sul-fate (BaSO4) particles, which are introduced in almost every catheter material to make it radiopaque. The loss of BaSO4 particles between the silicon bonds essentially leaves microscopic holes in the catheter, leaving areas of increased vulnerability that render the catheter prone to rupture (Fig. 1). Interestingly, more BaSO4-related cracks were observed in silicone than in polyurethane catheters.

Pictures of Ruptured Port-a-cath

A, Overview (×100) of catheter at site of rupture.

B, Magnification of rupture site (×232) shows additional surface defect in close proximity to rupture site.

C, Magnification of same catheter more distant from rupture site (×515) shows multiple surface defects.

D, Further magnification (×1290) shows hole in catheter after release of BaSO4 particles.

Medical Research by

Dr. Moritz Wildgruber